LEVAPOR

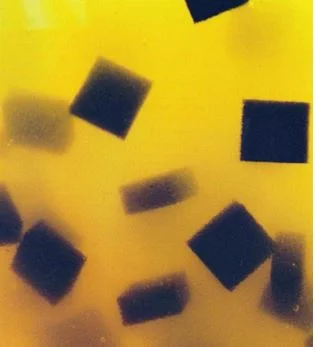

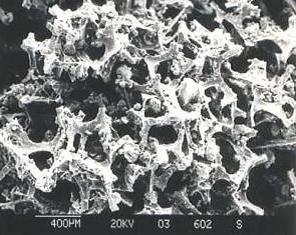

LEVAPOR carrier is an excellent biochip choice for the biological treatment process of wastewater. LEVAPOR carrier is made of porous, flexible, easily fluidisable plastic foam cubes, impregnated with adsorbing pigments. The carriers become colonized very quickly by microorganisms, resulting in bioprocess that has higher efficiency and stability, and capable of regenerating the adsorbing capacity biologically.

Fields of LEVAPOR application includes:

- Biotreatment of municipal and industrial effluents especially in nitrification/denitrification and removal of persistent and hazardous pollutants.

- Biological gas treatment, including acidifying pollutants,like chloroorganics, mercaptans, NH3 and H2S.

- Processes applying reuse of water, like fish hatcheries and aquacultures.

- Fermentation of bioproducts.

Benefits of using LEVAPOR in wastewater treatment system includes:

- 50 to 400% higher removal efficiency than with suspended biomass

- remarkably higher process stability

- remarkably lower excess sludge production

- Only requires 12 to 15% degree of reactor filling instead of usual 30 to 70%.

- Buffer toxic shock loadings

- higher removal of persistent, hazardous pollutants

- Short bioprocess startup period

PBI is the exclusive distributor of LEVAPOR in Indonesia.

“We abuse land because we regard it as a commodity belonging to us. When we see land as a community to which we belong, we may begin to use it with love and respect.”